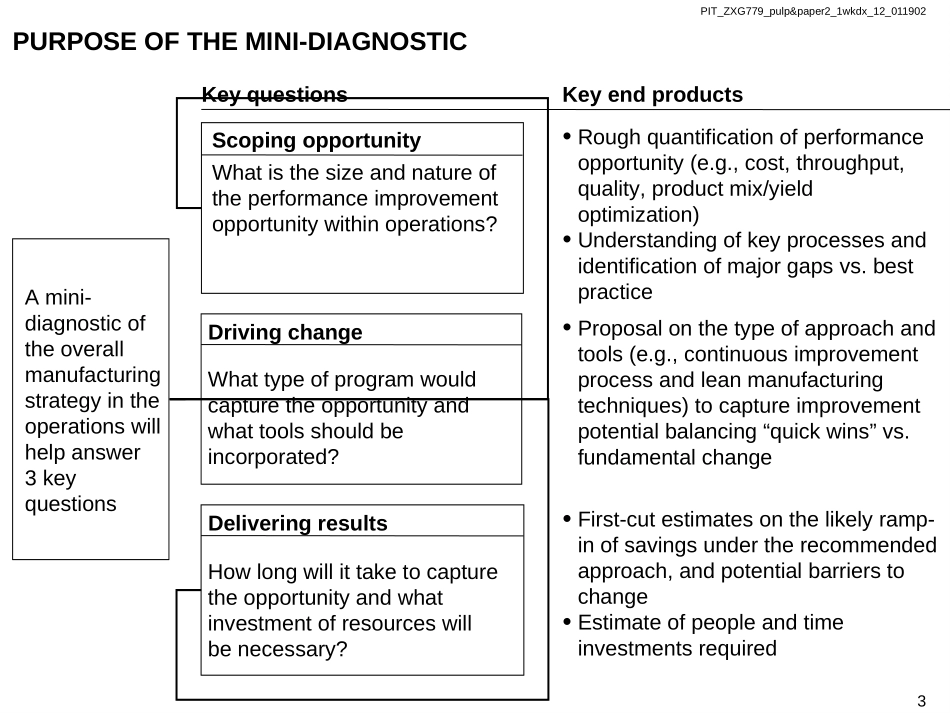

PIT_ZXG779_pulp&paper2_1wkdx_12_011902KickoffClient12DiagnosticDiscussiondocumentCONFIDENTIALThisreportcontainsinformationthatisconfidentialandproprietarytoMcKinsey&CompanyandissolelyfortheuseofMcKinsey&Companypersonnel.Nopartofitmaybeused,circulated,quoted,orreproducedfordistributionoutsideMcKinsey&Company.Ifyouarenottheintendedrecipientofthisreport,youareherebynotifiedthattheuse,circulation,quoting,orreproducingofthisreportisstrictlyprohibitedandmaybeunlawful.Client12–Pulp&PaperIndustryPIT_ZXG779_pulp&paper2_1wkdx_12_0119022TODAY’SDISCUSSION•Discussbackgroundinformation(wordmemo)andoverallobjectives(p.2,3,4fromoriginalproposal)•Identifykeyissuesandrefinedatarequestasneeded(p.5,6,7)•Reviewproposedworkplan,logisticsandteamstructure(p.8,9)•Identifyweakspots/infotocollectpre-diagnostic(e.g.,KPIs,benchmarks,etc.)PIT_ZXG779_pulp&paper2_1wkdx_12_0119023PURPOSEOFTHEMINI-DIAGNOSTICScopingopportunityWhatisthesizeandnatureoftheperformanceimprovementopportunitywithinoperations?DeliveringresultsHowlongwillittaketocapturetheopportunityandwhatinvestmentofresourceswillbenecessary?Amini-diagnosticoftheoverallmanufacturingstrategyintheoperationswillhelpanswer3keyquestionsKeyendproducts•Roughquantificationofperformanceopportunity(e.g.,cost,throughput,quality,productmix/yieldoptimization)•Understandingofkeyprocessesandidentificationofmajorgapsvs.bestpracticeDrivingchangeWhattypeofprogramwouldcapturetheopportunityandwhattoolsshouldbeincorporated?•Proposalonthetypeofapproachandtools(e.g.,continuousimprovementprocessandleanmanufacturingtechniques)tocaptureimprovementpotentialbalancing“quickwins”vs.fundamentalchange•First-cutestimatesonthelikelyramp-inofsavingsundertherecommendedapproach,andpotentialbarrierstochange•EstimateofpeopleandtimeinvestmentsrequiredKeyquestionsPIT_ZXG779_pulp&paper2_1wkdx_12_0119024PROPOSEDAPPROACH:10-DAYDIAGNOSTICPROCESS•Visit,observe,andconductanalysisoftheoperation(s)across3areas–Operationsperformanceandpotential(cost,throughput,quality,materialflow,etc.)–Coreprocessperformance(order-to-ship,maintenancemanagement,CI,etc.)andorganizationaldesign–Barrierstosuccess•IdentifymajorimprovementareasSynthesizetheresultsoftheeffort•Roughestimateofsizeandnatureoftheopportunity•Howtocaptureitandwheretostart•Perspectiveonresourcerequirementsandbarrierstosuccess•High-levelestimateonramp-inofsavingsforawell-executedprogramPhase1Phase2Phase3DatarequestandpreparationOn-siteobservationsandanalysisSynthesisandpresentation5daysDay(-10)-23days•Gatherdata(asmuchaspossible)priortoon-sitevisittomaximizevalueofvisit(datarequestsentinadvancewithsomeminordiscussionstoclarifydata)•Conduct1-2-dayvisitatheadofficetoreview–Theorganization–Productmixandflowsfromwoodlandstocustomersandkeydecisionsdrivers(e.g.,marginsbygrade,needsandprofitabilityofcustomersegments)–Corporatedecisionprocessesinfluencingoperations–e.g.,productionplanningprocess–Uniqueconditionsatfacilitiestovisit•HoldintroductorydiscussionswithkeymanagerstorefineapproachandidentifyimprovementhypothesesPIT_ZXG779_pulp&paper2_1wkdx_12_0119025MAINDIAGNOSTICWORKSTREAMSINPHASE2AssessingcoreoperationsperformanceandpotentialAssessingperformanceofcorefunctionsandcross-functionalprocesses,andorganizationdesignUnderstandingthebarrierstosuccessDescription•Developvaluestreammapfromrawmaterialtocustomer–understan...