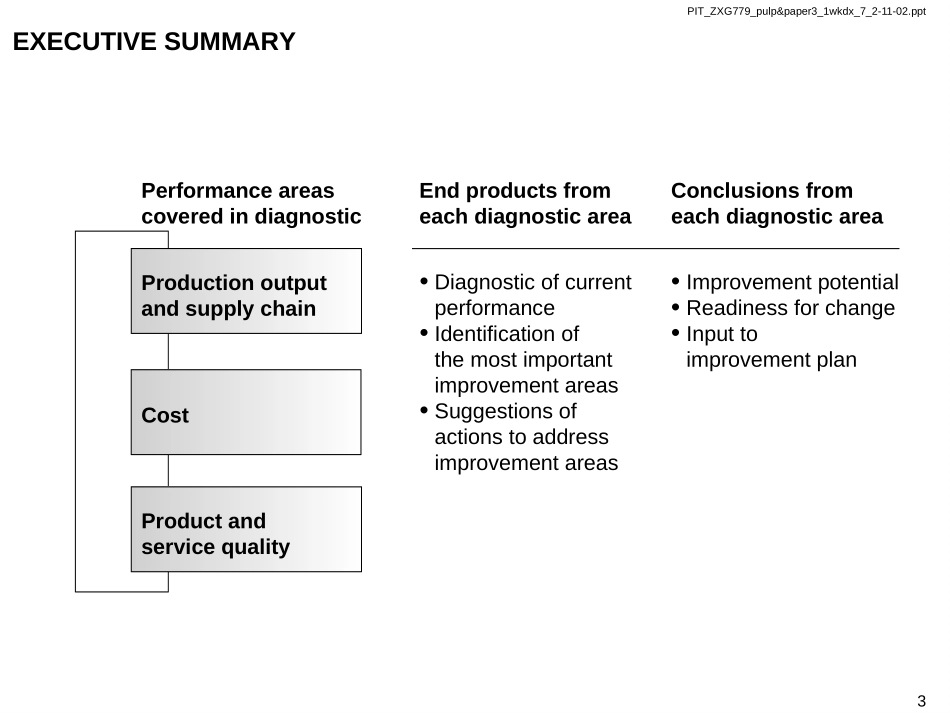

PIT_ZXG779_pulp&paper3_1wkdx_7_2-11-02.pptCONFIDENTIALDiscussionDocument,Version1.0DateThisreportcontainsinformationthatisconfidentialandproprietarytoMcKinsey&CompanyandissolelyfortheuseofMcKinsey&Companypersonnel.Nopartofitmaybeused,circulated,quoted,orreproducedfordistributionoutsideMcKinsey&Company.Ifyouarenottheintendedrecipientofthisreport,youareherebynotifiedthattheuse,circulation,quoting,orreproducingofthisreportisstrictlyprohibitedandmaybeunlawful.OperationalDiagnosticCLIENT7–PULP&PAPERINDUSTRYPIT_ZXG779_pulp&paper3_1wkdx_7_2-11-02.ppt2OPERATIONALDIAGNOSTICDefinitionValueApproach•Preparationofdiagnostic•Diagnosticofplantmill•CommunicationoffindingsPIT_ZXG779_pulp&paper3_1wkdx_7_2-11-02.ppt3PerformanceareascoveredindiagnosticEndproductsfromeachdiagnosticareaProductionoutputandsupplychain•Diagnosticofcurrentperformance•Identificationofthemostimportantimprovementareas•SuggestionsofactionstoaddressimprovementareasCostProductandservicequalityConclusionsfromeachdiagnosticarea•Improvementpotential•Readinessforchange•InputtoimprovementplanEXECUTIVESUMMARYPIT_ZXG779_pulp&paper3_1wkdx_7_2-11-02.ppt4Isyourproductionprocessstabilized?Stabilizeoperationsbeforestartingfull-blownleantransformationStartfull-blowntransformationtoleanoperationssystemFocusedimprovementsandselectiveapplicationofleantoolsgivequickshort-termimpactandstabilizeoperationsFull-blownleantransformationsecuresfundamentalandcon-tinuousimprovementsleadingtolong-termcompetitiveadvantageBelowtopquartileindustryperformanceStillsignificantlow-hangingfruitopportunitiesCustomer-definedspecif-icationsnotalwaysmet(<90%),e.g.,quality,anddeliverytimeNon/limitedsystematictrackingofoperationalperformanceBasicproblem-solvingandimplementationskillsnotwidelyspreadTopquartileindustryperformanceIncreasinglydifficulttoachieveimprovementsCustomer-definedspecificationsconsistentlymet(>90%)Daily/weeklytrackingofperformanceondepart-mentlevelBasicproblem-solvingandimplementationskillswidelyusedStableUnstableDIAGNOSTICAPPROACHOVERVIEWPIT_ZXG779_pulp&paper3_1wkdx_7_2-11-02.ppt5OPERATIONALDIAGNOSTICDefinitionValueApproach•Preparationofdiagnostic•Diagnosticofplantmill•CommunicationoffindingsPIT_ZXG779_pulp&paper3_1wkdx_7_2-11-02.ppt6DIAGNOSTICVALUEOrganizationalvisionProductionsystemphilosophyImprovementpotentialActionplantocaptureContinuousimprovementandeliminationofwasteStabilityandefficiencyFlowandflexibilityTimingAugSeptOctNovHeader5SSOPsPerformancemanagementImprovementtimelineClient7PIT_ZXG779_pulp&paper3_1wkdx_7_2-11-02.ppt7OPERATIONALDIAGNOSTICDefinitionValueApproach•Preparationofdiagnostic•Diagnosticofplantmill•CommunicationoffindingsPIT_ZXG779_pulp&paper3_1wkdx_7_2-11-02.ppt8Leader:Teammembers:Name(Location1)Name(Location2)Name(Location3)Name(Location4)Name(Location1)Name(Location1)CoreteamresourcesContinuousdailyaccesstowell-connectedmiddlemanagerservingasa“guide”•Identifyandensureaccesstotherightpeople•TransferknowledgeaboutfacilityAccessto•Plantmanager•Operationsmanager•Maintenancemanager•Productionschedulingresources•Otherkeyinformationsources(e.g.,processengineer)SiteresourcesRESOURCESPIT_ZXG779_pulp&paper3_1wkdx_7_2-11-02.ppt9ActivitiesDIAGNOSTICPROCESS•Gatherdatapriortodiagnosticstart•Holdintroductorydiscussionswithplantmanager•Holdkick-offmeetingwithmanagementandotherkeyresources•Runanalyse...