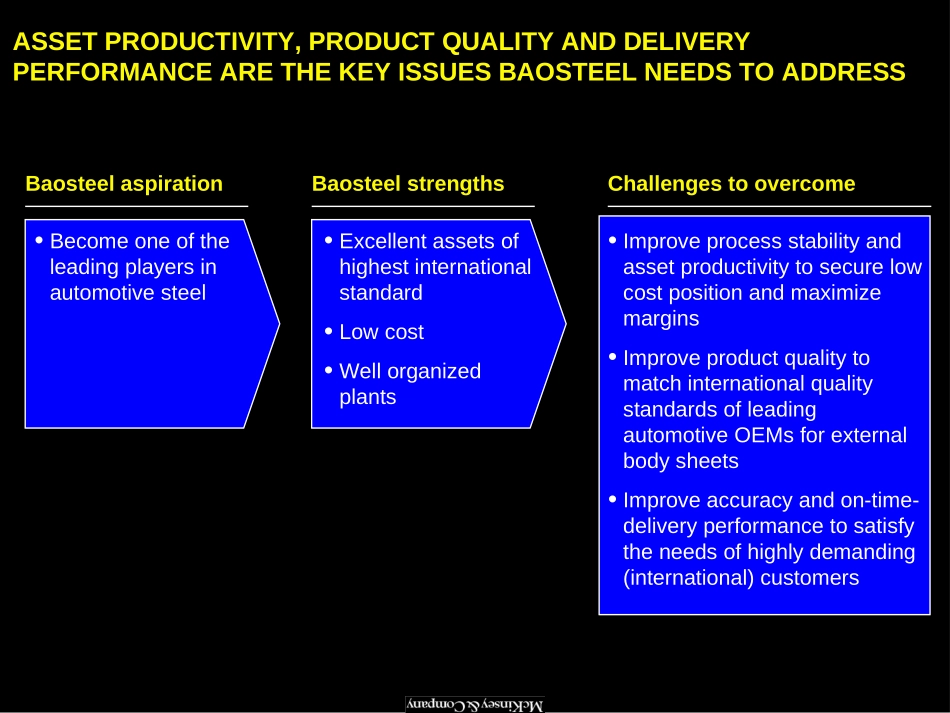

BS/020328/SH-KO(2000)ImprovingCapacityStability,ProductQualityandDeliveryPerformancethroughLeanManufacturingImplementationCONFIDENTIALKickoffDocumentMarch26,2002Thisreportissolelyfortheuseofclientpersonnel.Nopartofitmaybecirculated,quoted,orreproducedfordistributionoutsidetheclientorganizationwithoutpriorwrittenapprovalfromMcKinsey&Company.ThismaterialwasusedbyMcKinsey&Companyduringanoralpresentation;itisnotacompleterecordofthediscussion.BS/020328/SH-KO(2000)2•Backgroundandissuestobeaddressed•Projectdeliverables&diagnosticapproach•Workingarrangementsandinitialdatarequest•NextstepsBS/020328/SH-KO(2000)3ASSETPRODUCTIVITY,PRODUCTQUALITYANDDELIVERYPERFORMANCEARETHEKEYISSUESBAOSTEELNEEDSTOADDRESSChallengestoovercome•Improveprocessstabilityandassetproductivitytosecurelowcostpositionandmaximizemargins•ImproveproductqualitytomatchinternationalqualitystandardsofleadingautomotiveOEMsforexternalbodysheets•Improveaccuracyandon-time-deliveryperformancetosatisfytheneedsofhighlydemanding(international)customersBaosteelaspiration•BecomeoneoftheleadingplayersinautomotivesteelBaosteelstrengths•Excellentassetsofhighestinternationalstandard•Lowcost•WellorganizedplantsBS/020328/SH-KO(2000)4ASBAOSTEELHASEXCELLENTASSETS,REQUIREDIMPROVEMENTCANBEACHIEVEDTHROUGHUPGRADEDSKILLS&CAPABILITIES,ANDSYSTEMExampleofmeasurement•OEE•YieldImprovementlevers•Operatingskills•Productionscheduling•Debottleneckingefforts&investmentAssetproductivityDeliveryperformanceProductqualityImprovementlevers•Operatingskills•ProductionschedulingthroughouttheinternalchainExampleofmeasurement•Percentageoforderfulfilled•LeadtimeImprovementlevers•Operatingskills(stabilization&optimization)•Qualitymanagementsystems&processesExampleofmeasurement•Downgrading•ScrapBS/020328/SH-KO(2000)5THETWOHOTROLLEDCOILLINESHASBEENSELECTEDASAPILOTDUETOITSCENTRAL,CRITICALROLEINTHEWHOLEPROCESSFocusofthepilotSteelmakingHotrollingColdrollingGalvanizingRawmaterials•Critical,centralrolefortheoverallproductqualityanddeliveryperformance,aswellas,assetproductivity•RepresentativeasapilottodeveloponoverallapproachtoberolledoutAutomotiveOEMsBS/020328/SH-KO(2000)6•Backgroundandissuestobeaddressed•Projectdeliverables&diagnosticapproach•Workingarrangementsandinitialdatarequest•NextstepsBS/020328/SH-KO(2000)7PhaseIIIPlantwideroll-out•Systematicplantwidetraining•Implementationofselectedleantoolsthroughouttheplant•Realizedtangibleimprovementsthroughouttheplant•Institutionalizedperformancetrackingandmonitoringsystem•ContinuousprocessandorganizationtodrivefurtherimprovementEndproductsKeyactivities(notexhaustive)PhaseIILeantransformationpilotonhotrolledcoillineLeanmanufacturingsystemdiagnostic•Systematicanalysisofmanufacturingsystemtoidentifyproductqualityanddeliveryperformanceissuesaswellasmajorassetproductivityshortcomings•RootcauseanalysisofmajorissuesAssessmentofimprovementpotentialEstimateofthefinancialvaluePrioritizationofmosturgentproductquality,deliveryperformanceandassetproductivityissuesSelectionofleantoolstobeappliedPilotplanforhotrolledcoillineSelectedtrainingtoprojectteamandmanagementAssessmentoforganizationalreadinessInterviewBaosteelhotrolledcoillinemanagementandpersonnelAnalyzeexistingproductquality,deliveryperformancesandassetproductivity,andcomparetobestpracticeHaveworkshopsandbrainstormingsessionswithBaosteelmana...