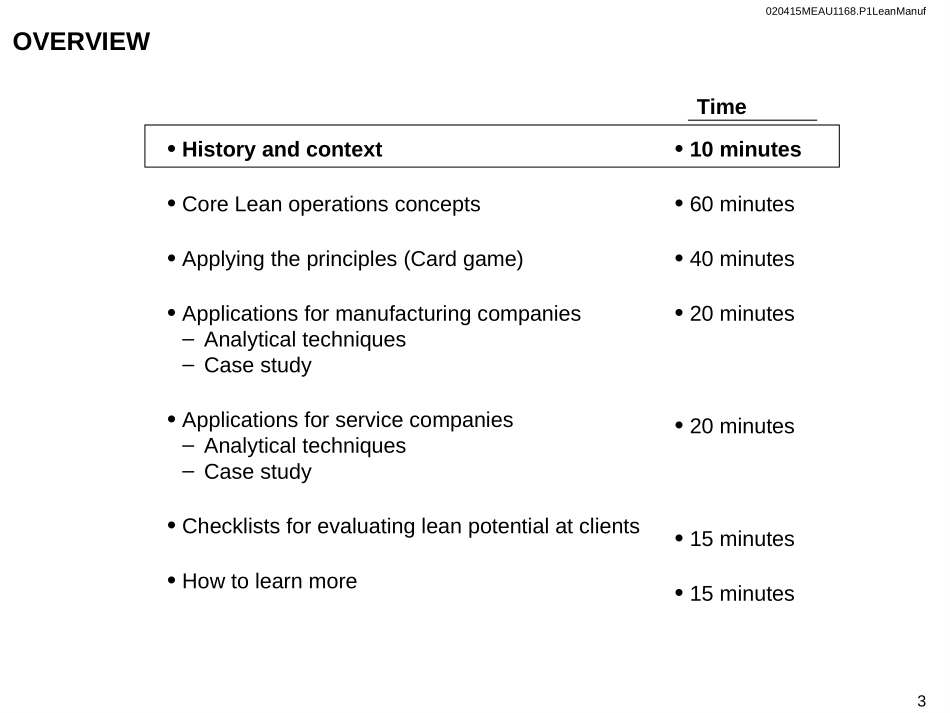

020415MEAU1168.P1LeanManufAnIntroductiontoLeanManufacturingTomCarlin(SYD),RamiKarjian(AT),KateMein(MEL)May2002Thisreportissolelyfortheuseofclientpersonnel.Nopartofitmaybecirculated,quoted,orreproducedfordistributionoutsidetheclientorganisationwithoutpriorwrittenapprovalfromMcKinsey&Company.ThismaterialwasusedbyMcKinsey&Companyduringanoralpresentation;itisnotacompleterecordofthediscussion.May2002020415MEAU1168.P1LeanManuf2OBJECTIVES•IntroduceLeanmanufacturingconceptsandillustrateapplicationinbothmanufacturingandservicesettings•Highlightpreliminarydiagnostictoolsandanalysistohelpframeopportunities•ProvideachecklisttohelpidentifyifLeanimprovementopportunitiesexistatmanufacturingandserviceclients020415MEAU1168.P1LeanManuf3OVERVIEW•Historyandcontext•CoreLeanoperationsconcepts•Applyingtheprinciples(Cardgame)•Applicationsformanufacturingcompanies–Analyticaltechniques–Casestudy•Applicationsforservicecompanies–Analyticaltechniques–Casestudy•Checklistsforevaluatingleanpotentialatclients•HowtolearnmoreTime•10minutes•60minutes•40minutes•20minutes•20minutes•15minutes•15minutes020415MEAU1168.P1LeanManuf4WHATISLEANMANUFACTURING?020415MEAU1168.P1LeanManuf5•Justashopfloorthing•Limitedtorepetitiveassembly•Animprovementprogram•Amenuoftoolsandtechniques•Justashopfloorthing•Limitedtorepetitiveassembly•Animprovementprogram•AmenuoftoolsandtechniquesLEANPRODUCTION–BASICDEFINITIONLeanisnot...Leanproductionis...Anintegratedsystemofprinciples,operatingpractices,andelementsthatpursuesoptimumstreamlining,improvedqualityandwasteeliminationAnintegratedsystemofprinciples,operatingpractices,andelementsthatpursuesoptimumstreamlining,improvedqualityandwasteelimination020415MEAU1168.P1LeanManuf6THECREATIONOFLEAN—THETOYOTAPRODUCTIONSYSTEM•TaichiiOhnodevelopedthe‘Toyotaproductionsystem’’emphasizing‘Just-in-time,’Autonomation,‘Pull’andregularcontinuousimprovement•ToyotaMotorCompanyachievedmassproductionefficiencyinalowvolume,highdiversityenvironment•‘CatchupwithAmericanautomobileindustryin3years/Contextandfactors•ToyodafatherandsonpairmovedfromToyodaAutomatedLoomCompanytovehicles•Developedanautomatedloomin1902as‘Jidoka’•FacedwithsmallandhighlydiverseJapanesevehiclemarketandscarcecapital,especiallyafterWWII60yearsofdevelopmentToyotafoundedJIT1933WWII195019601970198019902000TPSasasystemSupplierdevelopmentTransplants020415MEAU1168.P1LeanManuf7HighMediumDemandvariabilityContinuousServiceDiscreteassemblyHotelsBanks/InsuranceHospitalsAutomotive:allmajorproducersProcesstypeConsumerelectronicsMetalsandminingFocusonprocessstabilityandmainte-nanceFocusonvaluestreamandcustomerPulpandpaperFocusonprocessflowandflexibleworksystemsAPPLICATIONOFLEAN020415MEAU1168.P1LeanManuf8“LEAN”OPERATIONSCREATEACOMPETITIVEADVANTAGEValueofUSD100investedfor5years,February2001*Excludingexchangeratefluctuations**Alusuisse,Pechiney,Alcan,KaiserAlu,andCapralSource:Datastream;McKinseyanalysisToyotaJapanAutomobileindex184155AlcoaAluminumcompetition**255139DowChemicalUSChemicalsindexDuPontUSChemicalsindexDomtarUSBasicIndustriesindex228143159139158143LeanoperationscanbeimplementedinprocessindustriesEarlyadopterscangainacompetitiveadvantage020415MEAU1168.P1LeanManuf9OVERVIEW•Historyandcontext•CoreLeanoperationsconcepts•Applyingtheprinciples(Cardgame)•Applicationsformanufacturingcompanies–Analyti...