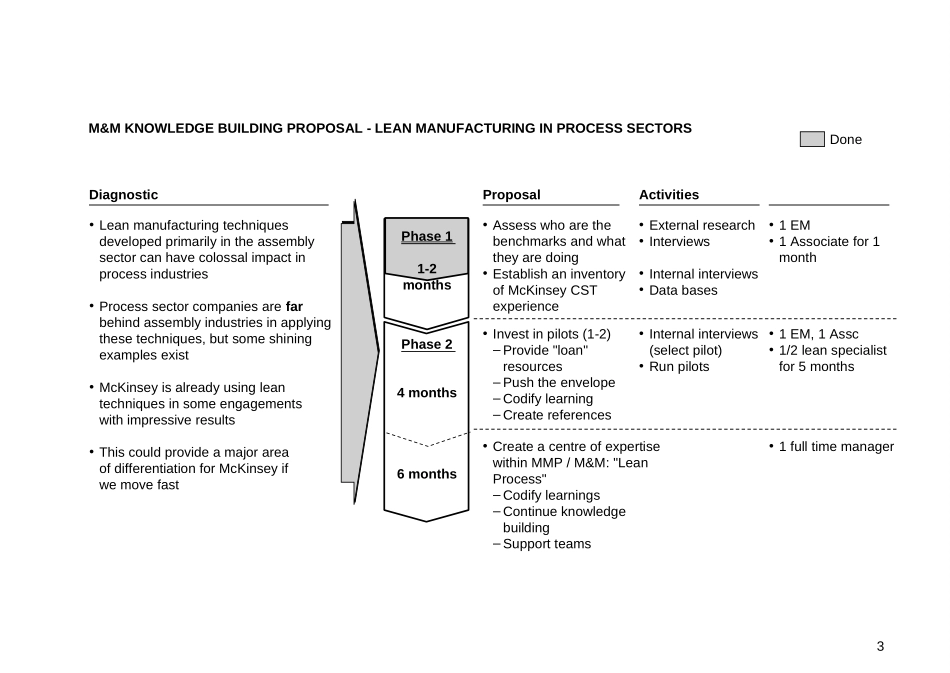

CONFIDENTIALThisreportissolelyfortheuseofclientpersonnel.Nopartofitmaybecirculated,quoted,orreproducedfordistributionoutsidetheclientorganizationwithoutpriorwrittenapprovalfromMcKinsey&Company.ThismaterialwasusedbyMcKinsey&Companyduringanoralpresentation;itisnotacompleterecordofthediscussion.SurveySummaryParis,March26,1999SurveyofApplicationsofLeanManufacturingToolsandMethodsinProcessIndustriesBruceSimpson/PAOEtienneColas/PAOJohannEggerth/GE-CG2TABLEOFCONTENTS•Objectiveoftheinitial3-weekphase•Definitionof"LeanManufacturing"•Surveyresults•Annexes3M&MKNOWLEDGEBUILDINGPROPOSAL-LEANMANUFACTURINGINPROCESSSECTORSDiagnostic•Leanmanufacturingtechniquesdevelopedprimarilyintheassemblysectorcanhavecolossalimpactinprocessindustries•Processsectorcompaniesarefarbehindassemblyindustriesinapplyingthesetechniques,butsomeshiningexamplesexist•McKinseyisalreadyusingleantechniquesinsomeengagementswithimpressiveresults•ThiscouldprovideamajorareaofdifferentiationforMcKinseyifwemovefastProposal•Assesswhoarethebenchmarksandwhattheyaredoing•EstablishaninventoryofMcKinseyCSTexperiencePhase11-2months•Externalresearch•Interviews•Internalinterviews•DatabasesActivities•1EM•1Associatefor1monthPhase24months6months•Investinpilots(1-2)–Provide"loan"resources–Pushtheenvelope–Codifylearning–Createreferences•Internalinterviews(selectpilot)•Runpilots•1EM,1Assc•1/2leanspecialistfor5months•CreateacentreofexpertisewithinMMP/M&M:"LeanProcess"–Codifylearnings–Continueknowledgebuilding–Supportteams•1fulltimemanagerDone4KNOWLEDGEBUILDING:LEANMANUFACTURINGSEGMENTSNumberofprocessstepsTrainsSkipsTurbinesCarsElectronicsAppliancesPaperSteelAluminumChemicalsBevCarsBottlesDiapersManyFewFewManyNumberofunits1.MMPteamsStefanRoggenhoferGernotStrubeArneMayJensHendrikPagelPeterWillatsRainerUlrich3.JointMMP/M&MleadershipBruceSimpson,MichaelDenham,EtienneColas,AndréLévisse,RubenVerhoeven2.MMPteam2PeterWillatsFelixBrueck4.MMPteam4MartinRieggerBetrandOlivarStefanRoggenhoferRubenVerhoevenDavidColeal5OBJECTIVEOFTHEINITIAL3-WEEKPHASE¶Asafirststeptowardsdevelopingacomprehensiveapproachtoapply"LeanManufacturing"conceptsinProcessIndustries,theteamconductedasurveyofFirmandexternalknowledgeandapplicationsinthearea,inorderto:•IdentifywhichCSTshaveapplied"Lean"approaches•Investigatenon-clientcompanieswith"Lean"experience•Identifytheimpact-qualitativeandquantitative-ofMcKinsey"Lean"engagements•Listtoolsandmethodsusedduring"Lean"programs•Determineopportunitiesandlimitsfor"Lean"applicationsinProcessIndustries6DEFINITIONOF"LEANMANUFACTURING"¶MostlyderivedfromtheToyotaProductionSystem,"LeanManufacturing"aimsateliminatingwastefromtheentireorganizationbyworkingonitskeycauses:variabilityandinflexibility.WechoosetoorganizethenumeroustoolsofLeanManufacturingaccordingtothreebasicblocks:•Justintimeisprimarilyaimedateliminatingoverproductionbyrestructuringphysicalandinformationflows•Peoplemobilizationisnecessarytoenforcestandardizationandeliminatethenumeroussourcesofvariability•MachineefficiencyisimprovedthroughTPMandcapacityanalysis¶MoredetaileddefinitionsaregiveninAnnexe17SURVEYRESULTS¶LeantoolsarealreadyusedbyafewProcessIndustryCSTs(Exhibit1)¶TheseCSTinitiativeshavehadnoticeableimpact:•Fromaquantitativepointofviewtheimpacthasbeenmostoften,whilenotexclusively,onlogisticsandserviceperformance(Exhibit2)andmea...