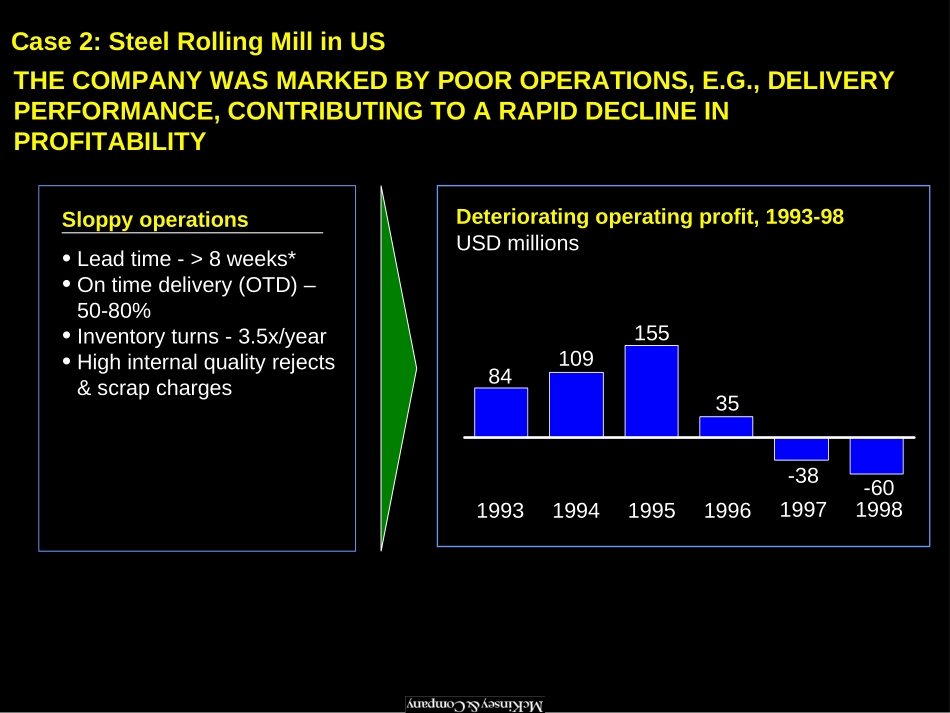

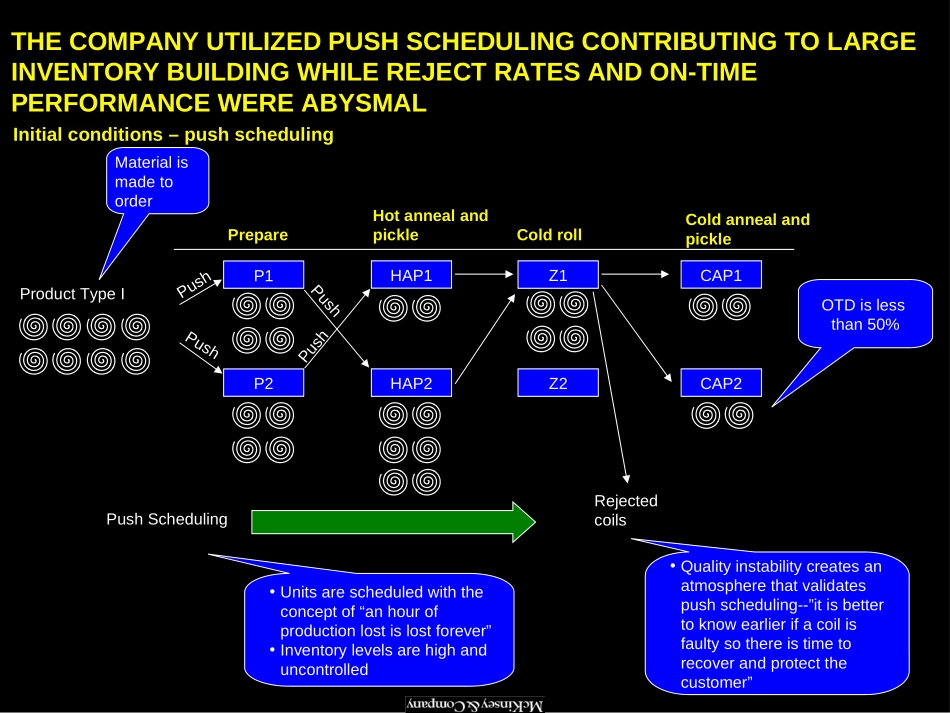

BS/01205/SH-WS-Appe.(2000)1APPENDIX•Case2:SteelRollingMill(US)•Case3:Long(Europe)ProductsCompanyBS/01205/SH-WS-Appe.(2000)2THECOMPANYWASMARKEDBYPOOROPERATIONS,E.G.,DELIVERYPERFORMANCE,CONTRIBUTINGTOARAPIDDECLINEINPROFITABILITY199319941995199619971998Deterioratingoperatingprofit,1993-98USDmillionsSloppyoperations•Leadtime->8weeks*•Ontimedelivery(OTD)–50-80%•Inventoryturns-3.5x/year•Highinternalqualityrejects&scrapcharges8410915535-38-60*SignificantlyhigherthandirectcompetitorsCase2:SteelRollingMillinUSBS/01205/SH-WS-Appe.(2000)3Source:McKinseyanalysisTHECOMPANYUTILIZEDPUSHSCHEDULINGCONTRIBUTINGTOLARGEINVENTORYBUILDINGWHILEREJECTRATESANDON-TIMEPERFORMANCEWEREABYSMALPrepareP1P2HotannealandpickleHAP1HAP2ColdrollZ1Z2ColdannealandpickleCAP1CAP2ProductTypeIPushPushPushPushRejectedcoilsPushScheduling•Qualityinstabilitycreatesanatmospherethatvalidatespushscheduling--”itisbettertoknowearlierifacoilisfaultysothereistimetorecoverandprotectthecustomer”•Unitsarescheduledwiththeconceptof“anhourofproductionlostislostforever”•InventorylevelsarehighanduncontrolledMaterialismadetoorderOTDislessthan50%Initialconditions–pushschedulingBS/01205/SH-WS-Appe.(2000)4CoilPrepareHotannealandpickleColdrollColdannealandpickleTemperSlitAP1HAP1Z1CAP1T1S1S2416S4S5T2CAP2Z2HAP2P2BCZ3•Flexibility=instability•ConstantexpeditingS3Plant1Plant23identicalcoilsare“flexibly”routedalong3separateoperationalflowpathsIDENTICALPRODUCTSFLOWEDALONGMULTIPLEPRODUCTIONPATHSSEVERELYHAMPERINGCONTINUOUSPROBLEMSOLVINGInitialconditions–pathinstabilityProductionunitsBS/01205/SH-WS-Appe.(2000)5StandardizingworkPullschedulingVisualmanagementandshopfloorcontrols•Applyingcoilstoorderslaterintheproductionprocess•Varyinginventorytypesforapplication(cycle,buffer,safety)•Reducingproductcomplexity•Makingthenormalvs.abnormalconditionobvious•Enforcingdiscipline•Standardizinganauditprocess•Sameproduct•Samepath•SameprocessSource:McKinseyanalysisTHESOLUTIONTOTHECOMPANY’SOPERATIONALPROBLEMSTOIMPROVEDELIVERYPERFORMANCEANDQUALITY(ANDCOST)FOCUSEDONTHREEAREAS:PULLSCHEDULING,STANDARDIZINGWORK,ANDVISUALPLANTMANAGEMENTANDCONTROLBS/01205/SH-WS-Appe.(2000)6DETERMININGWHICHTYPEOFPULLSYSTEMWORKEDBESTINTHISENVIRONMENTWASTHEFIRSTSTEPOptionsPullfromfinishedgoodsbaseduponreplenishmentsignalMeltCastHSMHAPR-millCAPSlitFinishedgoodsOrderBuildtoorderbaseduponproductioninstructionMeltCastHSMHAPR-millCAPSlitOrderLateorderapplicationfromstandardworkinprocessinventoryMeltCastHSMHAPR-millCAPSlitFinishedgoodsOrderBuildtoreplenishPullfromwhitebandapplicationstocks123FinishedgoodsSELECTEDOPTIONBS/01205/SH-WS-Appe.(2000)7THEABILITYTODETERMINECOILQUALITY,THENEEDTOREDUCEPRODUCTCOMPLEXITY,ANDADESIREFORSHORTLEADTIMESDETERMINEDTHEAPPLICATIONINVENTORY’SLOCATIONSource:McKinseyanalysisHotannealandpicklePrimary,HSMandreceiveColdrollingColdannealandpickleSlitApplicationpullstockRejectionrates23%1%7%4%•SincemostrejectionsareontheHAPline,pullstockshouldbeafterHAPLeadtimes:2weeks2days(every2weeks)1-3days2days(every2weeks)1-3days•Tocreateacompetitiveleadtimeadvantageof4days-3weeks,pullstockshouldbeaslateaspossibleReductionofgaugeandwidthcomplexityGaugeproliferation(from2to16)Widthproliferation(from3to19)•Tomaintainasmallandmanageablenumberofpullcoils,stockneedstobeheldbeforethereducingmillPilotpullstockEXAMPLEPRODUCTPullscheduling–choosinginventoryst...