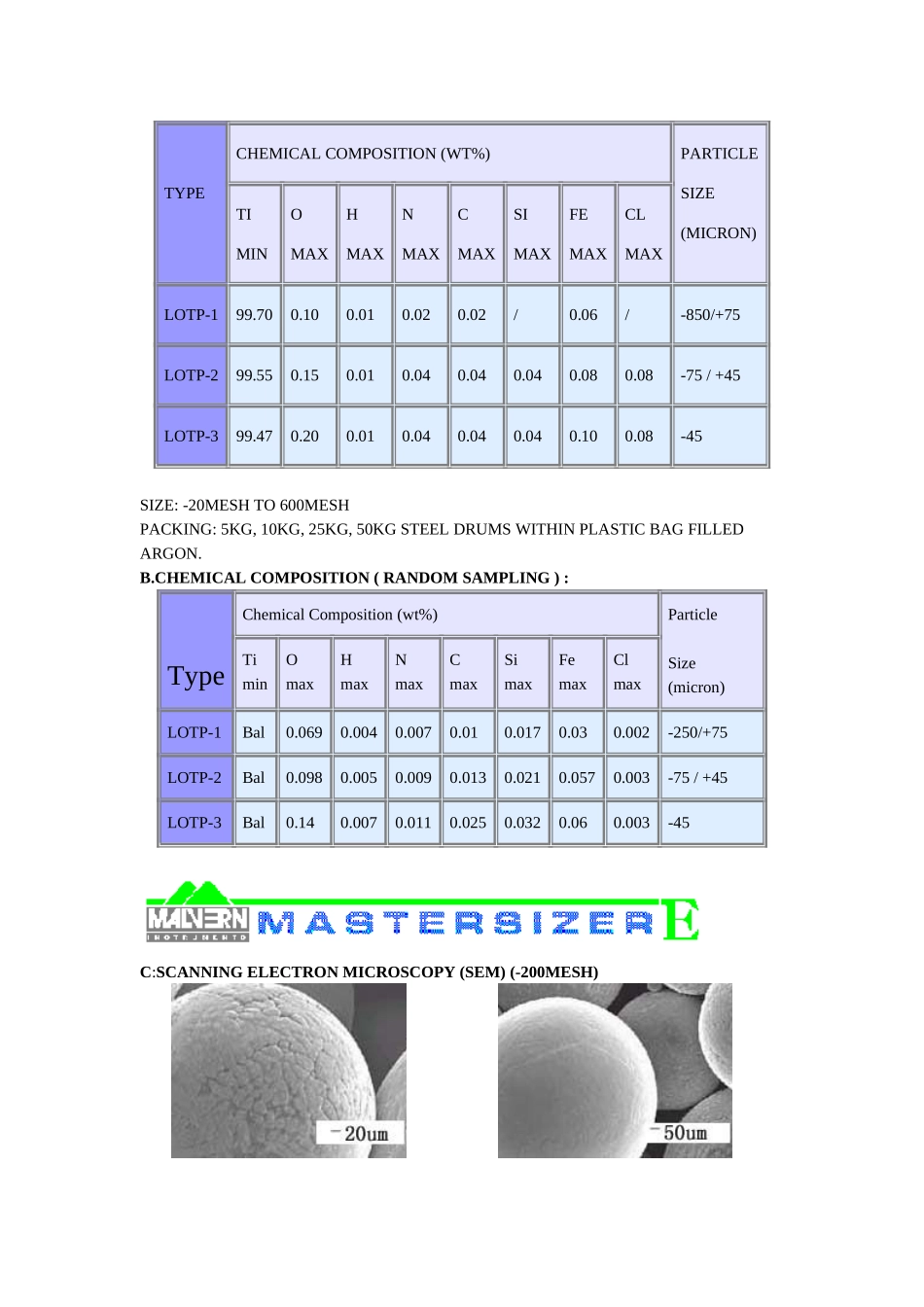

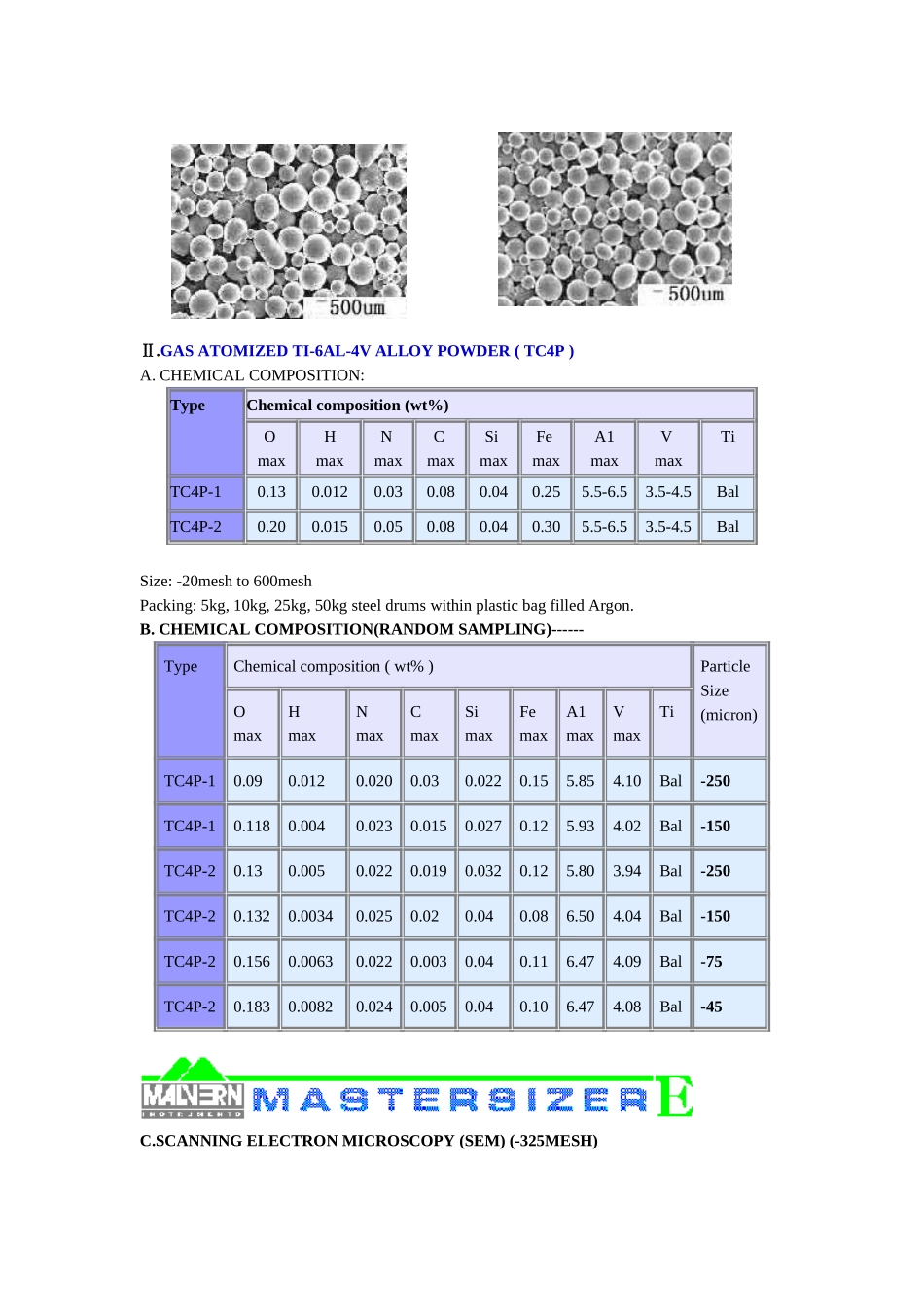

陕西邦圳钛业股份公司AboutusBongenTitanium(China)CoLtd.isaworldleaderinresearch,development,manufacturing,andsalesofC.P.TitaniumandTitaniumalloypowderproducts.OurproductionisbasedonBongen'spatentedInductionMeltingInertGasAtomization(IMIGA)technology.IMIGAprocessisthenewesttechnologyformanufacturingTitaniummetalpowder.Theadvantageofthistechnologyisthattheheatingprocessinvolvesinductionmeltingwithoutcrucibles,whichsignificantlylowerscostthanCruciblesmeltingatomizationtechnologyandPREPprocess.Itcanmeetallpowdermetallurgy,HIP,andMIMproductsmarketneeds.Sinceit'sbeginningin1996asametalpowdermanufacturerandsupplier,BongenhasbeencommittedtodevelopingandmanufacturinghighqualityTitaniummetalpowderproducts.Today,Bongenhasaninternationalmarketingnetworkandtheindustry'slargestR&Dcapability.BesidesGas-AtomizedC.P.TiandTi-6Al-4Valloypowder,Bongenalsomanufactureshydride-dehydrogenated(HDH)TipowderandatomizedotherTialloypowdersaccordingtothecustomer'srequest.Andnow,Bongencompanyhasbuiltthebiggestsupersonicgas-atomizedTitaniummetalpowderproductionlineandisamajorTitaniummetalpowdersupplierfortheaerospace,biomedical,medical,defense,autoparts,andsportinggoodindustriesintheworld.Atpresent,ouroutputcomprises120MTatomizedsphericalC.P.Tipowderand120MTatomizedsphericalTi-6Al-4Valloypowderperyear.Inaddition,weproduce150MTHDHhighpurityTimetalpowdereachyear.Currently,wearebuildingournewR&Dcenterandexpandingoutproductionlinetoreachanoutputcapacityof1000-1200MTTitaniumandothermetalpowderseachyear.BongenisproudtohaveachievedISO9002accreditationAwardedbytheInternationalStandardsOrganizationonJun02,2000.BongenisuniquelyqualifiedtoprovideyouwithanykindofTitaniummetalpowderyouarelookingfor.Wehopetocooperatewithyou.ProductsandCharacteristicsBongenisaninnovatorintheresearch,development,andmanufacturingofTi,Tialloypowders.Itspatentedtechnology(IMIGAprocess)allowsittoproduce240MTatomizedTiandTialloypowderseachyear.AndBongen’sTitaniumrawmaterialsaremanufacturedatISO9001certifiedEUandCN-mills.Ourfourmaintypesofproductsare:1.GASATOMIZEDLOWOXYGENSPHERICALTITANIUMPOWDER(LOTP)A.CHEMICALCOMPOSITION:TYPECHEMICALCOMPOSITION(WT%)PARTICLESIZE(MICRON)TIMINOMAXHMAXNMAXCMAXSIMAXFEMAXCLMAXLOTP-199.700.100.010.020.02/0.06/-850/+75LOTP-299.550.150.010.040.040.040.080.08-75/+45LOTP-399.470.200.010.040.040.040.100.08-45SIZE:-20MESHTO600MESHPACKING:5KG,10KG,25KG,50KGSTEELDRUMSWITHINPLASTICBAGFILLEDARGON.B.CHEMICALCOMPOSITION(RANDOMSAMPLING):TypeChemicalComposition(wt%)ParticleSize(micron)TiminOmaxHmaxNmaxCmaxSimaxFemaxClmaxLOTP-1Bal0.0690.0040.0070.010.0170.030.002-250/+75LOTP-2Bal0.0980.0050.0090.0130.0210.0570.003-75/+45LOTP-3Bal0.140.0070.0110.0250.0320.060.003-45C:SCANNINGELECTRONMICROSCOPY(SEM)(-200MESH)Ⅱ.GASATOMIZEDTI-6AL-4VALLOYPOWDER(TC4P)A.CHEMICALCOMPOSITION:TypeChemicalcomposition(wt%)OmaxHmaxNmaxCmaxSimaxFemaxA1maxVmaxTiTC4P-10.130.0120.030.080.040.255.5-6.53.5-4.5BalTC4P-20.200.0150.050.080.040.305.5-6.53.5-4.5BalSize:-20meshto600meshPacking:5kg,10kg,25kg,50kgsteeldrumswithinplasticbagfilledArgon.B.CHEMICALCOMPOSITION(RANDOMSAMPLING)------TypeChemicalcomposition(wt%)ParticleSize(micron)OmaxHmaxNmaxCmaxSimaxFemaxA1maxVmaxTiTC4P-10.090.0120.0200.030.0220.155.854.10Bal-250TC4P-10.1180.0040.0230.0150.0270.125.934.02Bal-150TC4P-20.130.0050.0220.0190.0320.125.803.94Bal-250TC4P-20.1320.00340.0250.020.040.086.504.04Bal-150...