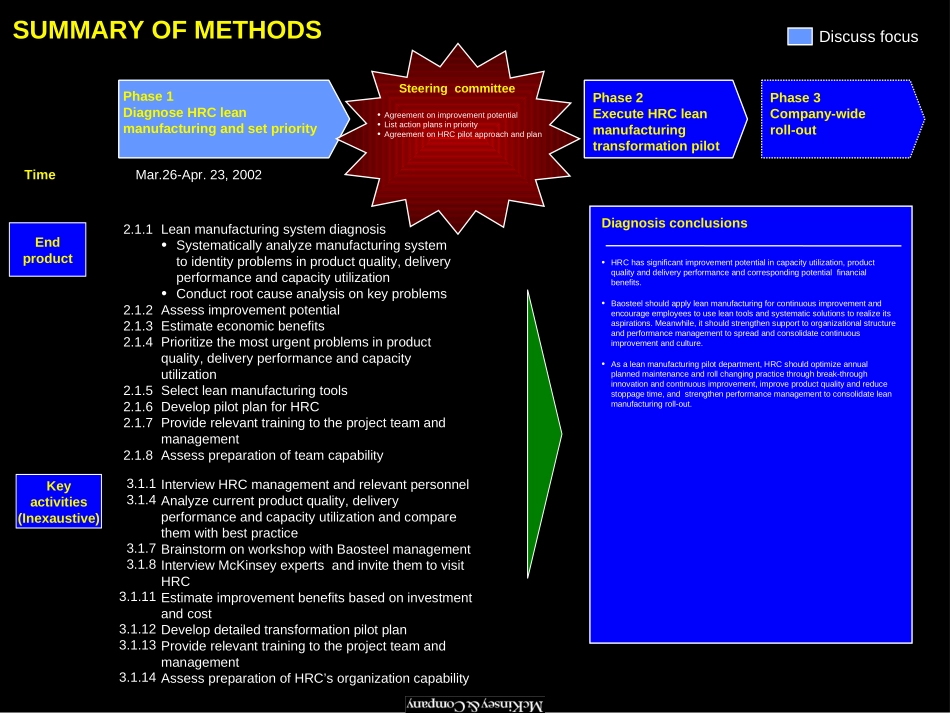

BS/020416/SH-WZ(2000)CONFIDENTIALEnhanceCapacityStability&Utilization,ProductQualityandAccuracy&TimelyDeliveryPerformancethroughLeanTransformationThisreportissolelyfortheuseofclientpersonnel.Nopartofitmaybecirculated,quoted,orreproducedfordistributionoutsidetheclientorganizationwithoutpriorwrittenapprovalfromMcKinsey&Company.ThismaterialwasusedbyMcKinsey&Companyduringanoralpresentation;itisnotacompleterecordofthediscussion.April24,2002LeanManufacturingDiagnosticPhaseProgressReviewBS/020416/SH-WZ(2000)2SUMMARYOFMETHODSDiscussfocusEndproductKeyactivities(Inexaustive)TimePhase1DiagnoseHRCleanmanufacturingandsetpriorityMar.26-Apr.23,2002Steeringcommittee•Agreementonimprovementpotential•Listactionplansinpriority•AgreementonHRCpilotapproachandplanPhase2ExecuteHRCleanmanufacturingtransformationpilotPhase3Company-wideroll-out2.1.12.1.22.1.32.1.42.1.52.1.62.1.72.1.8Leanmanufacturingsystemdiagnosis•Systematicallyanalyzemanufacturingsystemtoidentityproblemsinproductquality,deliveryperformanceandcapacityutilization•ConductrootcauseanalysisonkeyproblemsAssessimprovementpotentialEstimateeconomicbenefitsPrioritizethemosturgentproblemsinproductquality,deliveryperformanceandcapacityutilizationSelectleanmanufacturingtoolsDeveloppilotplanforHRCProviderelevanttrainingtotheprojectteamandmanagementAssesspreparationofteamcapabilityInterviewHRCmanagementandrelevantpersonnelAnalyzecurrentproductquality,deliveryperformanceandcapacityutilizationandcomparethemwithbestpracticeBrainstormonworkshopwithBaosteelmanagementInterviewMcKinseyexpertsandinvitethemtovisitHRCEstimateimprovementbenefitsbasedoninvestmentandcostDevelopdetailedtransformationpilotplanProviderelevanttrainingtotheprojectteamandmanagementAssesspreparationofHRC’sorganizationcapability3.1.13.1.43.1.73.1.83.1.113.1.123.1.133.1.14•HRChassignificantimprovementpotentialincapacityutilization,productqualityanddeliveryperformanceandcorrespondingpotentialfinancialbenefits.•Baosteelshouldapplyleanmanufacturingforcontinuousimprovementandencourageemployeestouseleantoolsandsystematicsolutionstorealizeitsaspirations.Meanwhile,itshouldstrengthensupporttoorganizationalstructureandperformancemanagementtospreadandconsolidatecontinuousimprovementandculture.•Asaleanmanufacturingpilotdepartment,HRCshouldoptimizeannualplannedmaintenanceandrollchangingpracticethroughbreak-throughinnovationandcontinuousimprovement,improveproductqualityandreducestoppagetime,andstrengthenperformancemanagementtoconsolidateleanmanufacturingroll-out.DiagnosisconclusionsBS/020416/SH-WZ(2000)3EXECUTIVESUMMARYBaoSteelcurrentlyfacessignificantchallengesinsatisfyinggrowing,demandinganddifferentiatedcustomerneedsinabidtobecomeworld-classsteelcompany.Asthekeybottleneckpartoftheproductionchain,currentHRCperformanceonassetproductivity,productqualityanddeliveryperformanceneedstobesignificantlyimprovedforBaoSteeltosecureandstrengthenitscompetitivepositiontogrowmarketshareinanincreasinglycompetitiveenvironment.Topdownbenchmarkingwithexternalandhistoricalinternalbestpracticesaswellasbottomuprootcauseanalysisrevealssignificantreductionpotentialinmaintenancetime,rollchangetime,breakdown,speedloss,rework(includingdowngrade),anddeliveryleadtime.Potentialnearterm(withinnext12months)financialimpactacrossallthreeareascouldreachRMB200millionintotal,andmed-term(1-3years)financialimpactcouldbeR...