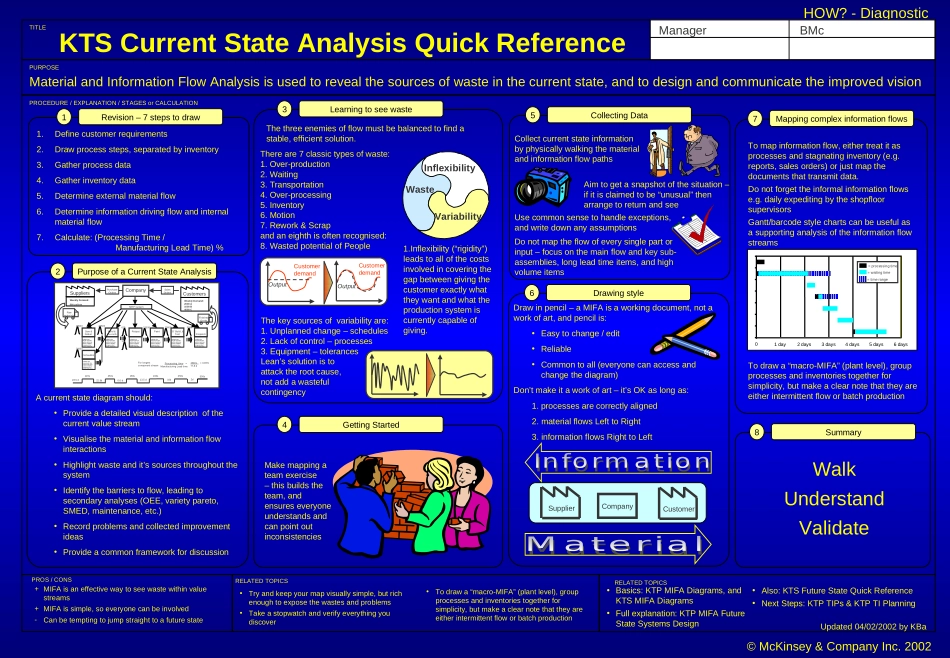

KTSCurrentStateAnalysisQuickReferenceTITLE•Tryandkeepyourmapvisuallysimple,butrichenoughtoexposethewastesandproblems•Takeastopwatchandverifyeverythingyoudiscover•Basics:KTPMIFADiagrams,andKTSMIFADiagrams•Fullexplanation:KTPMIFAFutureStateSystemsDesignHOW?-DiagnosticMaterialandInformationFlowAnalysisisusedtorevealthesourcesofwasteinthecurrentstate,andtodesignandcommunicatetheimprovedvision©McKinsey&CompanyInc.2002PROCEDURE/EXPLANATION/STAGESorCALCULATIONPURPOSEUpdated04/02/2002byKBaManagerBMc•Todrawa“macro-MIFA”(plantlevel),groupprocessesandinventoriestogetherforsimplicity,butmakeaclearnotethattheyareeitherintermittentfloworbatchproduction+MIFAisaneffectivewaytoseewastewithinvaluestreams+MIFAissimple,soeveryonecanbeinvolved-Canbetemptingtojumpstraighttoafuturestate•Also:KTSFutureStateQuickReference•NextSteps:KTPTIPs&KTPTIPlanningRELATEDTOPICSRevision–7stepstodraw11.Definecustomerrequirements2.Drawprocesssteps,separatedbyinventory3.Gatherprocessdata4.Gatherinventorydata5.Determineexternalmaterialflow6.Determineinformationdrivingflowandinternalmaterialflow7.Calculate:(ProcessingTime/ManufacturingLeadTime)%Acurrentstatediagramshould:•Provideadetailedvisualdescriptionofthecurrentvaluestream•Visualisethematerialandinformationflowinteractions•Highlightwasteandit’ssourcesthroughoutthesystem•Identifythebarrierstoflow,leadingtosecondaryanalyses(OEE,varietypareto,SMED,maintenance,etc.)•Recordproblemsandcollectedimprovementideas•ProvideacommonframeworkfordiscussionPurposeofaCurrentStateAnalysis2WeeklyDemand:2000A1000B4000CWeeklyDemand:500palletsSchaublinAvailabletimemanualcycletimemachinecycletimemachinereliabilitychangeovertimeshared/dedicatedSaw&DeburrAvailabletimemanualcycletimemachinecycletimemachinereliabilitychangeovertimeshared/dedicatedWeld&De-carbAvailabletimemanualcycletimemachinecycletimemachinereliabilitychangeovertimeshared/dedicatedRotajetAvailabletimemanualcycletimemachinecycletimemachinereliabilitychangeovertimeshared/dedicatedPaintAvailabletimemanualcycletimemachinecycletimemachinereliabilitychangeovertimeshared/dedicated‘G’Build,&TestAvailabletimemanualcycletimemachinecycletimemachinereliabilitychangeovertimeshared/dedicatedDispatchAvailabletimemanualcycletimemachinecycletimemachinereliabilitychangeovertimeshared/dedicated30001000013500600100225002850026000RawmaterialsFinishedGoodsMRPsystem10d180s13.5d28.5d120s250s240s250s2d500s22.5d0.6dProcessingtimeManufacturingLeadtimeForlongestcomponentstream=1540s=0.06%77.8dSuppliersCustomersCompanySalesOrdersPurchaseOrdersLearningtoseewaste3InflexibilityVariabilityWasteThereare7classictypesofwaste:1.Over-production2.Waiting3.Transportation4.Over-processing5.Inventory6.Motion7.Rework&Scrapandaneighthisoftenrecognised:8.WastedpotentialofPeople1.Inflexibility(“rigidity”)leadstoallofthecostsinvolvedincoveringthegapbetweengivingthecustomerexactlywhattheywantandwhattheproductionsystemiscurrentlycapableofgiving.CustomerdemandOutputCustomerdemandOutputThekeysourcesofvariabilityare:1.Unplannedchange–schedules2.Lackofcontrol–processes3.Equipment–tolerancesLean’ssolutionistoattacktherootcause,notaddawastefulcontingencyThethreeenemiesofflowmustbebalancedtofindastable,efficientsolution.RELATEDTOPICSMakemappingateamexercise–thisbuildstheteam,andensureseveryoneunderstandsandcanpointoutinconsistenciesAimtogetasnapshotofthesituation–ifitisclaimedtobe“unusual”thenarrangetoreturnandseeUsecommonsensetohandleexceptions,andwritedownanyassumptionsDrawinpencil–aMIFAisaworkingdocument,notaworkofart,andpencilis:•Easytochange/edit•Reliable•Commontoall(everyonecanaccessandchangethediagram)Don’tmakeitaworkofart–it’sOKaslongas:1.processesarecorrectlyaligned2.materialflowsLefttoRight3.informationflowsRighttoLeftCollectcurrentstateinformationbyphysicallywalkingthematerialandinformationflowpathsDonotmaptheflowofeverysinglepartorinput–focusonthemainflowandkeysub-assemblies,longleadtimeitems,andhighvolumeitemsTodrawa“macro-MIFA”(plantlevel),groupprocessesandinventoriestogetherforsimplicity,butmakeaclearnotethattheyareeitherintermittentfloworbatchproductionWalkUnderstandValidateTomapinformationflow,eithertreatitasprocessesandstagnatinginventory(e.g.reports,salesorders)orjustmapthedocumentsthattransmitdata.Donotforgettheinformalinformationflowse.g.dailyexpeditingbytheshopfloorsupervisorsGantt/barcodestylechartscanbeusefulasasupportinganalysisoftheinformationflowstreamsGettingStarted4CollectingData5Mappingcomplexinformationflows7Drawingstyle6Summary8PROS/CONSSupplierCustomerCompany01day2days3days4days5days6days=timerange=waitingtime=processingtime